Published on Feb. 15, 2024

Design and hygiene control of the site and production buildings

In this article we will talk about the design of the production site, the upkeep of the building and its surroundings which are the first items that contribute to the success of rearing SASSO breeding stock.

1 - Zoning

During the design of the production site the farmer should:

1-Prevent the introduction of pathogens on his farm

2-Prevent the multiplication of germs on his site

3-Prevent his livestock farm being a source of environmental contamination

These three pillars are the core of what is known as biosecurity.

The site is an enclosed space, access to which is controlled and should makes it possible:

- to control flows of people, materials, equipment and consumables

- to control the flows of live or dead animals

- to protect the farm animals from any contact with wild fauna.

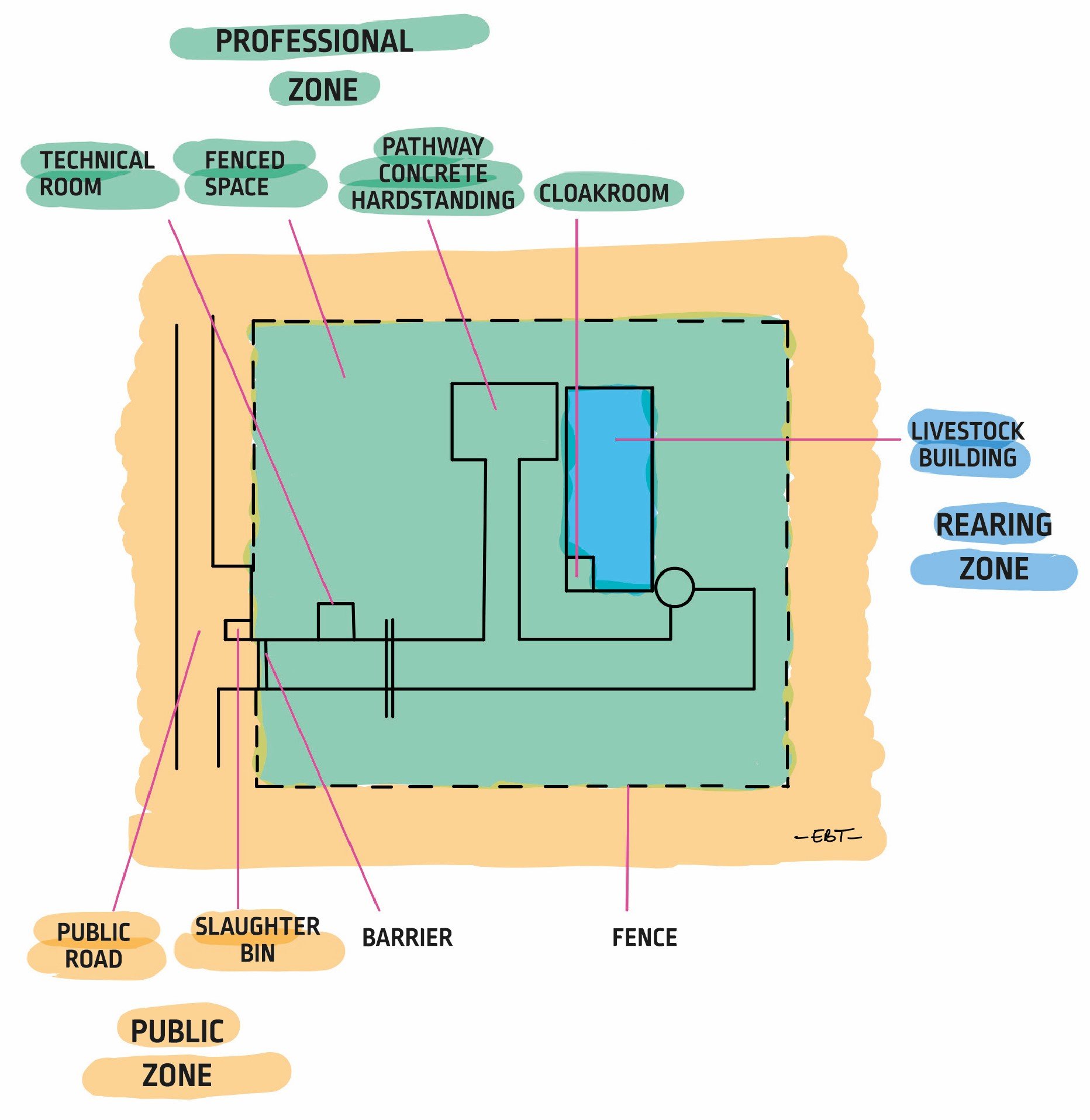

To do this three major zones should be clearly defined:

- A PUBLIC ZONE in which visitors may move about freely (e.g. administrative offices, road, car park)

- A PROFESSIONAL ZONE in which only authorised employees may move about (e.g. the storage barn, paths to buildings, cloakroom)

- A REARING ZONE reserved for animals and operators responsible for their care (e.g. the brooder house).

Each zone should be physically delimited (fencing, wall, fence) and only accessible via a cloakroom.

Entries and exits of farmers, equipment, eggs and animals, the arrival of raw materials and shipping of waste (eggs, cadavers) must be controlled and each circuit or flow must be separated from others in space or time.

2 - General hygiene

At all times the livestock farmer must ensure:

- the cleanliness and hygiene of the site and its surroundings, the entry cloakroom for personnel and equipment, the dispatch cloackroom for hatching eggs (HE), the store, the storage areas for waste (freezer, rendering bin)

- the correct operation of cleaning and disinfection tools

- the presence of bait for rodents and other pest

- water quality (annual or even half-yearly bacteriological control at the inlet to the building and at the end of the watering line).

In order to limit the risks on sites with several buildings the farmer will prefer rearing in single batches to rearing in multiple batches.

3 - Flows

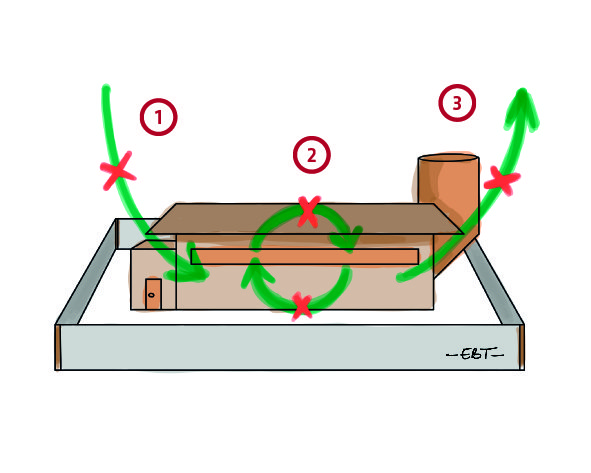

A) Vehicles

Entry of vehicles to the livestock site must be limited to the strict minimum. Access should be prohibited to any undesirable vehicle.

Delivery (feed, gas, other consumables, breeder pullets) or shipping (HE, cull hens) vehicles travel from farm to farm. These are excellent pathogen vectors. It is compulsory for them to be cleaned and disinfected before entering the livestock site.

The driver also travels from farm to farm. You do not know his health status. In no circumstances should he enter the building, even to help with tasks (e.g. pick-up).

A disinfection ramp located at the vehicle entrance makes disinfection routine, if it is used correctly.

During culling, if the site has several buildings and if these are not emptied simultaneously, the driver must not enter the site with his vehicle in order limit the hygiene risk of introducing a pathogen.

B) Equipment

Each building’s equipment must be specific to that building to limit the contamination risk. Entry of external equipment should be limited to the maximum.

Before entering the livestock building, it is compulsory for any equipment to be disinfected (washed before disinfection if possible).

A disinfection cloackroom is provided for this at the entrance to the building or the site.

C) People

Access to the livestock site and the building must be limited to people working with the animals: farmers, technicians, veterinary surgeons. Each person must use the cloakroom correctly.

It is tempting to ignore the cloakroom and go round it or not take into account its various zones, especially if you are in a hurry or tired. For this reason the cloakroom should be restrictive, i.e. it must have fences and barriers so that going through the cloakroom is compulsory.

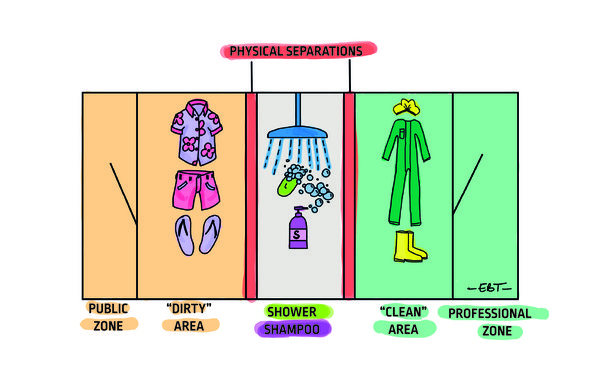

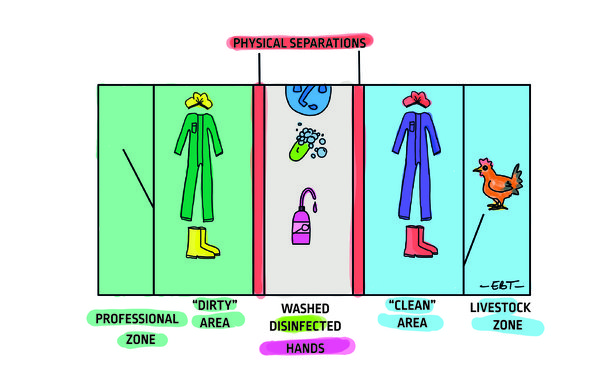

We recommend setting up cloakrooms in three zones.

For example, the cloakroom located at the entrance to the professional zone includes:

- an exterior area where people leave their normal clothing (clothes and shoes)

- an intermediate area where people take a full shower (body and hair) and disinfect their hands

- an interior area where people put on clothing specific to the farm, including underclothes, overalls, cap and shoes.

If the installation does not make it possible to take a shower and change clothes completely, it is desirable to provide at least overalls specific to the building and a water point for hand washing.

It is important that the cloakroom is disinfected frequently and regularly (at least once a week). In each building you should find a cloakroom which allows a change of clothing to put on the clothing specific to the building. The intermediate area must allow hands to be washed and disinfected.

Technical tip: A foot bath loses its effectiveness very quickly over time, technique particularly if it is regularly used. In order to prevent it becoming a source of germs, it is recommended that it is emptied, washed, disinfected and renewed at least once a day adhering to disinfectant concentrations provided by the manufacturer.

D) Waste

Waste is one of the main disease vectors in farming. When a livestock site is designed it is essential to plan for waste removal.

There are many sorts:

- cull hens

- cadavers

- eggs that are not able to be hatched, collected by the hatchery or under the responsibility of the farmer.

- droppings

- used disposable equipment

- waste water.

The cadavers must be stored in a freezer placed in each building before being put in the rendering bin just before the butcher comes. In order to avoid the slaughter truck entering the production site, the rendering bin should be located outside the site.